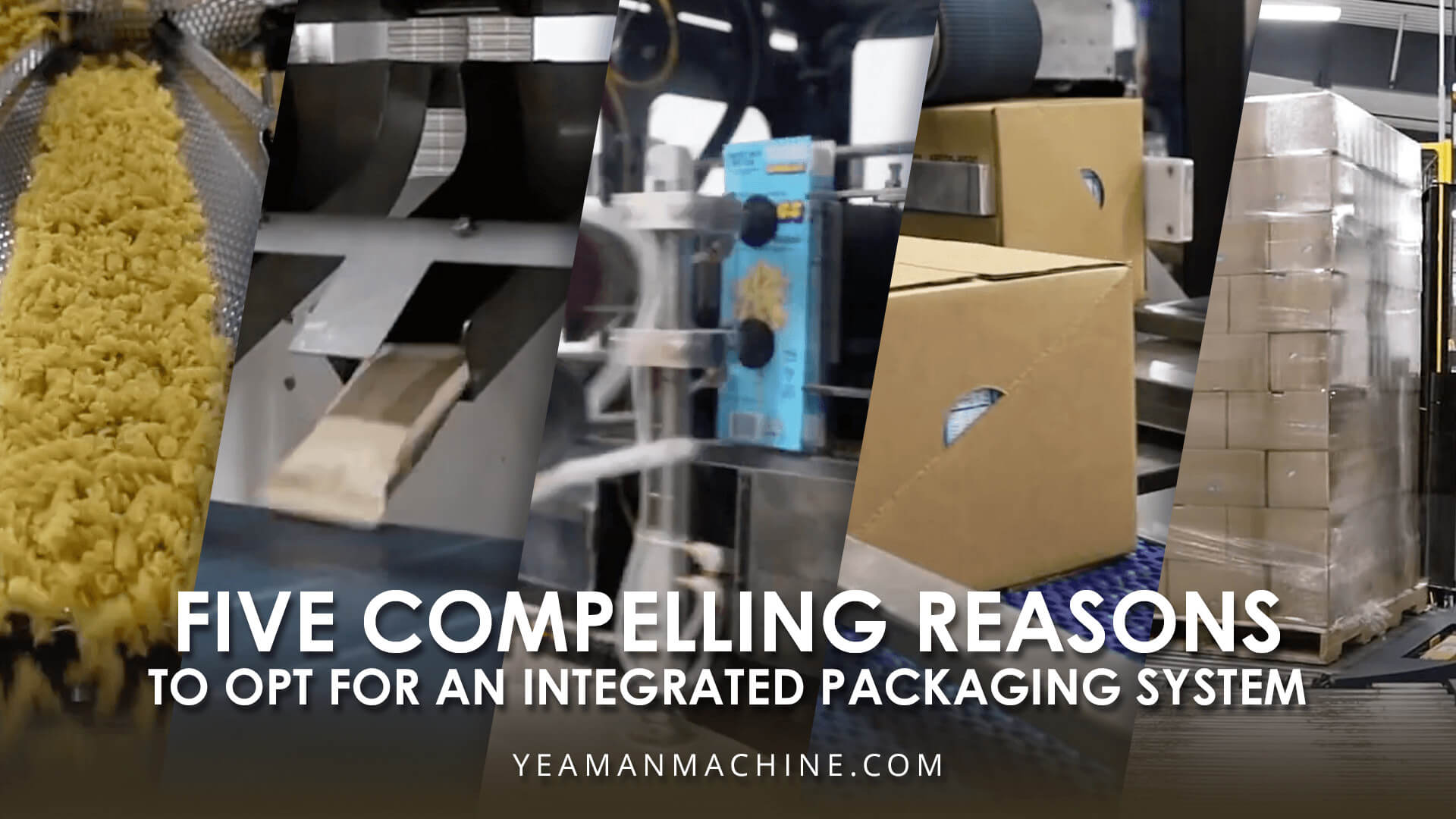

Integrated packaging systems offer a comprehensive solution to automate the entire packaging process, from the initial packaging of goods to the final stages of shipping. These systems provide a seamless flow of packaging automation, handling everything from raw products to pallets ready for shipment. Typically comprising multiple packaging machines and modules, integrated systems create a unified packaging line that oversees cartoning, code printing, tray packing, case packing, labeling, and palletizing. While the upfront investment for such a system may seem daunting, especially for new or smaller businesses, the long-term benefits far outweigh the initial costs. Here are five key reasons to consider investing in an integrated packaging system:

1. Initial Cost vs. Future Savings

As a manufacturing business expands, the inevitability of automation becomes apparent. You might start by automating one aspect of the packaging process, investing in a single packaging machine to meet immediate needs. However, as operations grow, additional automation becomes necessary, leading to investments in multiple machines over time. In hindsight, piecemeal automation can result in a significantly larger overall investment compared to opting for an integrated packaging system from the outset. Acquiring cartoners, case packers, and palletizers separately can be costlier. Many packaging machine manufacturers offer incentives such as deals or discounts for a comprehensive integrated system, streamlining costs in the long run.

2. Efficient Use of Floor Space and Modular Design

Floor space within a production facility is a valuable asset that should be utilized optimally. Consider the scenario where equipment accumulation over the years necessitates a move to a larger facility due to space constraints. This is a situation best avoided. Integrated systems, with their modular design, offer a tailored solution that can fit into small or unconventional spaces within the facility. Custom-built to maximize space efficiency, these systems are designed according to the specific floor plan, ensuring efficient use of available space.

3. Seamless Compatibility

Acquiring packaging equipment from different manufacturers over time can lead to a mix of machines that are incompatible with each other. Integrating such diverse machines into a cohesive packaging line may require additional equipment, such as various conveyors and robotics, incurring extra costs. Incompatibility issues can also lead to manual transfer of products between machines, slowing down the entire process and adding to the workload of staff. Investing in an integrated packaging system eliminates these compatibility hassles, ensuring a smooth and efficient packaging operation.

4. Reduction in Labor Costs

High labor costs and a shortage of skilled workers are significant challenges faced by manufacturing industries. Integrated packaging systems offer a solution by allowing businesses to allocate their workforce to more value-adding tasks. This results in a reduction in labor turnover rates, improved workplace conditions, and a decrease in the risk of repetitive-motion injuries among employees. By streamlining packaging processes, integrated systems help optimize labor resources and mitigate associated costs.

5. Simplified Maintenance and Service

Choosing an integrated packaging solution from a single manufacturer establishes a long-term partnership with a reliable service provider. This manufacturer becomes responsible for all repairs, spare parts, maintenance, and servicing of the packaging line. This streamlined approach is far more convenient than dealing with multiple manufacturers, each with its own set of services and support requirements. With a single partner overseeing all packaging needs, businesses can ensure compatibility, reliability, and optimal performance of their equipment.

At Yeaman Packaging Systems, we are committed to being that trusted partner. Lower your costs, enhance efficiency, and unlock the full potential of your packaging operations with our integrated solutions. If you're ready to invest in top-tier, cost-effective packaging solutions, contact us today for a quote and take the first step towards packaging excellence!