Vertical vs.

Horizontal

Enhance Your Packaging Process with Horizontal and Vertical Cartoners!

At Yeaman Packaging Machines, we specialize in optimizing your packaging operations through our high-quality Horizontal and Vertical Cartoners.

Unsure about choosing the right packaging machine for your product? Your decision centers on understanding your current and future packaging requirements.

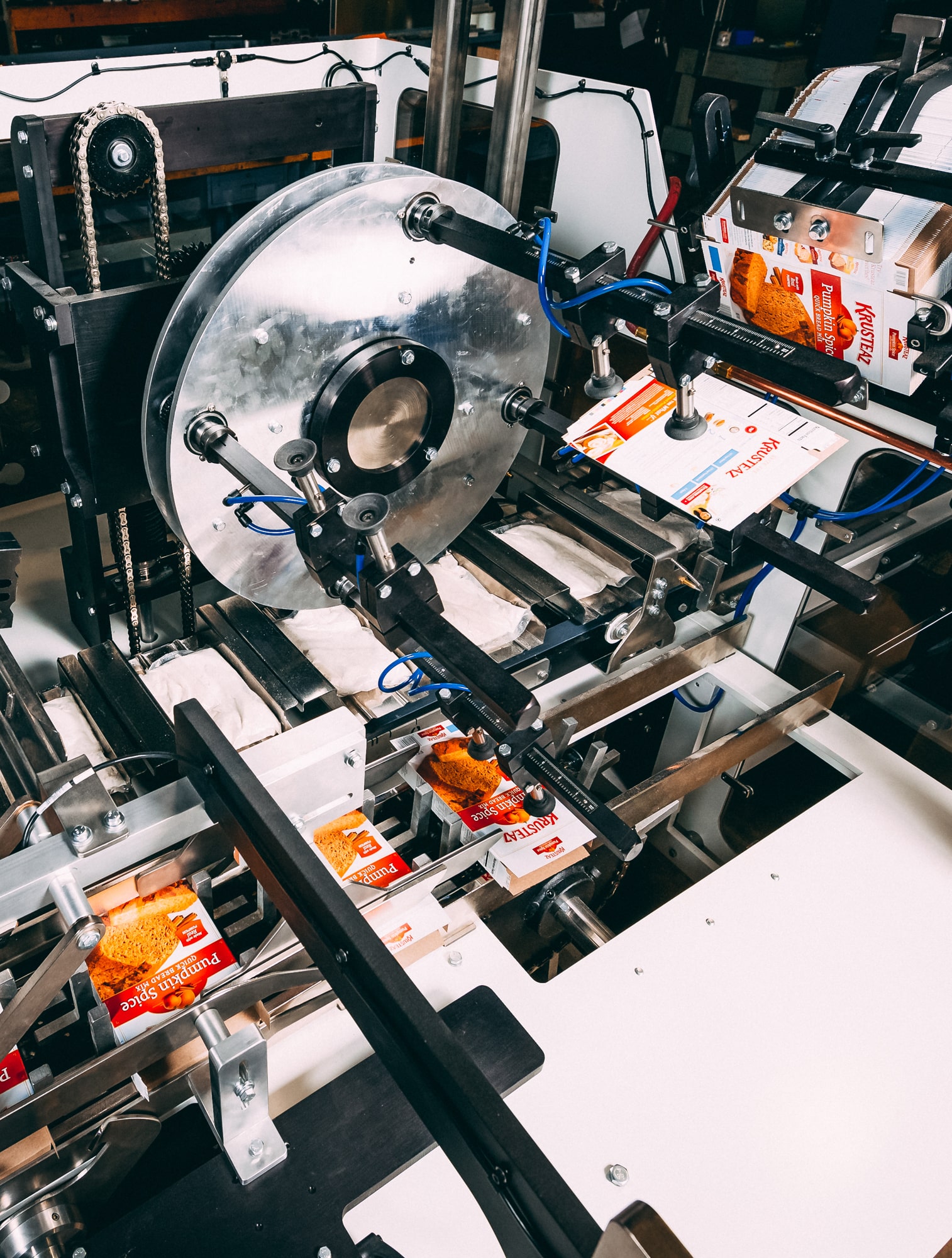

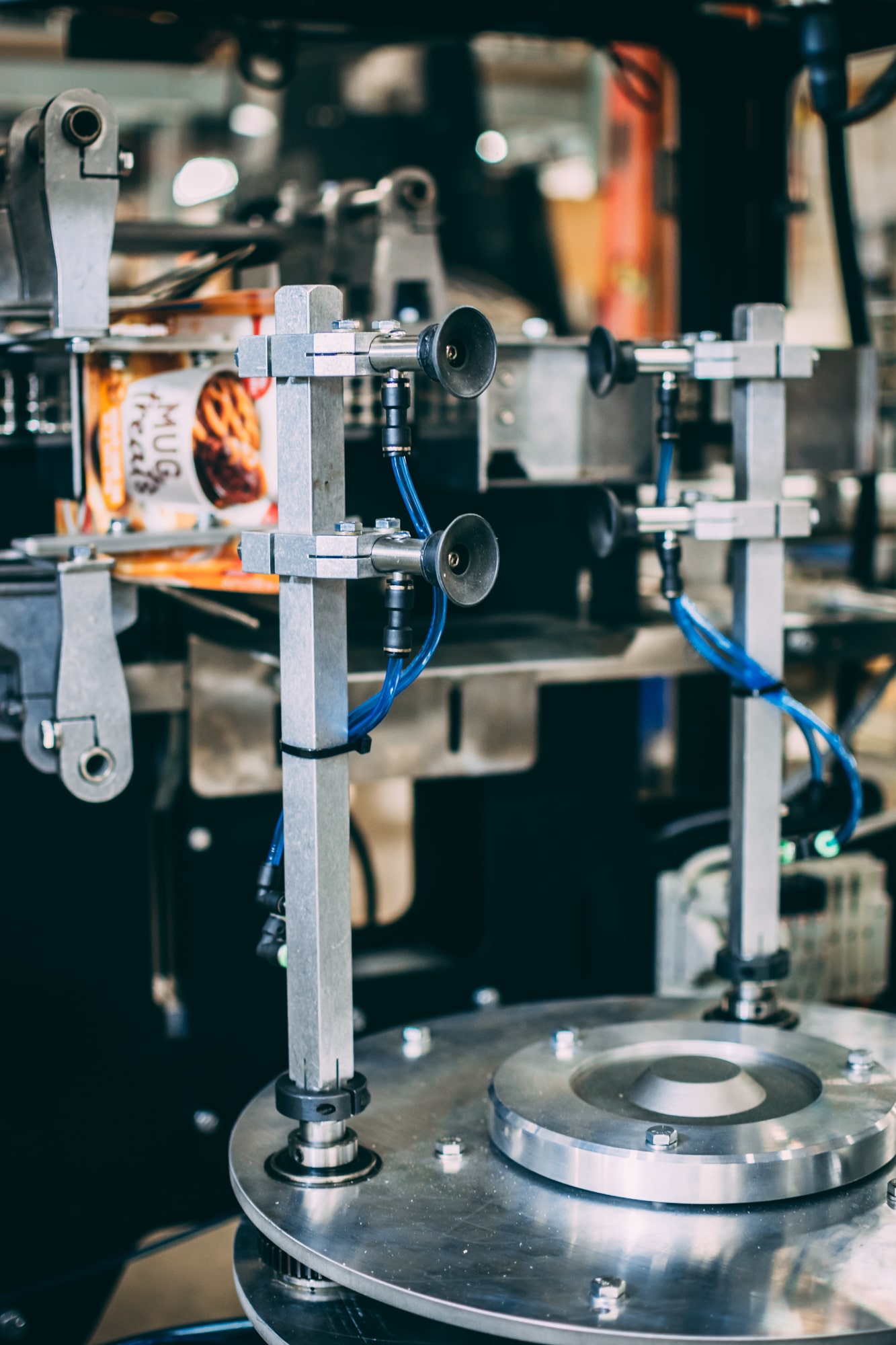

Let's explore the visual differences: a Horizontal Cartoner adopts an end-loaded method, pushing products into the carton from the side, while a Vertical Cartoner employs a top-loading approach, guiding or placing items into the carton from above. Even unconventional items like bags can be efficiently handled, utilizing a flex spout for top-loading.

Your choice depends on the intended use of your packing equipment. While either cartoning machine serves dedicated tasks effectively, our convertible Vertical Cartoner offers unmatched versatility. It empowers you to process multiple products both now and in the future. With interchangeable carton pockets and plowing modules, this cartoner machine supports various carton sizes and styles. Moreover, it facilitates different configurations for filling methods, ensuring seamless transitions between loose fill, bag-in-box, stick packs, and kits - all achievable on a single, adaptable machine!

Yeaman Packaging Machines presents the optimal solution for your food packaging needs, delivering efficiency, versatility, and reliability. Let us transform your packaging process today!

Which one handles your package and product?

Package Styles

- All

- Vertical

- Horizontal

Standard Seal

Auto Bottom

Tuck and Seal

Reverse Fold

Fifth Panel

Reverse Tuck

Economy Seal

Straight Tuck

Gable Top

Sift Proof

Product Types

Bag-in-Box

Bars

Blister Packs

Bottles

Cans

Cups

Dry Flowables

Jars and Vials

Kits

Loose-Fill with Pouch

Non-Food

Pouches and Sachets

Stick Packs

Trays

Twist Wraps